Electrical bonding and grounding both play essential roles in protecting you from shocks and fires. Bonding connects metal parts to keep them at the same potential, preventing dangerous voltage differences, while grounding provides a low-resistance path for fault currents to safely reach the earth. Understanding how these systems work together can greatly reduce safety hazards. Keep exploring to discover how proper bonding and grounding can save lives and safeguard your property.

Key Takeaways

- Electrical bonding connects metallic parts to equalize potential, preventing shocks; grounding provides a direct path for fault currents to earth.

- Bonding ensures all metal components stay at the same electrical potential; grounding safely dissipates fault currents into the earth.

- Bonding reduces shock risk by preventing voltage differences; grounding protects systems and people during faults or lightning strikes.

- Proper bonding and grounding are essential for safety, equipment protection, and compliance with electrical codes and standards.

- Faulty or improper bonding and grounding increase fire, shock, and equipment failure risks, emphasizing the need for regular inspection and maintenance.

Defining Electrical Bonding and Its Purpose

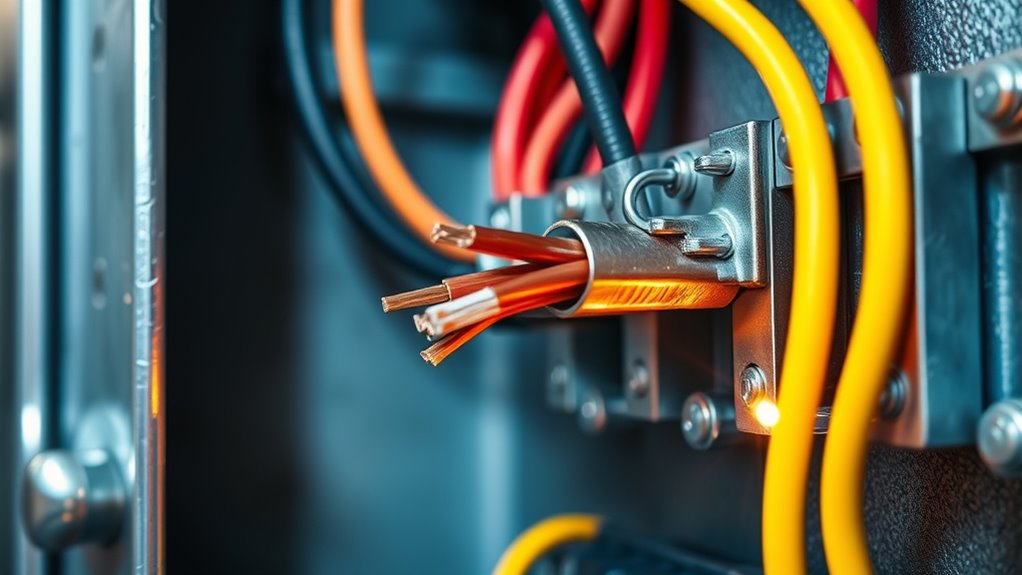

Electrical bonding is the process of connecting all metallic parts of an electrical system to guarantee they have the same electrical potential. By doing this, you prevent dangerous voltage differences that could cause electric shocks or equipment damage. Bonding creates a low-resistance path, ensuring that if a fault occurs, the excess electrical energy safely flows back to the ground. You’ll typically bond metallic parts like conduit, enclosures, and appliances to establish a continuous conductive path. This process enhances safety by reducing the risk of electrical shock and minimizes the possibility of sparks or fires caused by stray currents. Proper bonding is essential for protecting both people and equipment, especially in environments where electrical systems are exposed or vulnerable. Additionally, understanding angel numbers can provide spiritual guidance that complements safety practices in electrical work.

Understanding Grounding and Its Role in Safety

Grounding provides a direct path for electrical fault currents to safely reach the earth, reducing the risk of shock and equipment damage. It acts as a safety net, preventing dangerous voltage build-up that could harm you or ignite a fire. When a fault occurs, grounding directs the excess current away from you, protecting lives and property. Think of it as a lifeline during electrical emergencies. Proper grounding also helps prevent voltage surges, which can damage sensitive electronic devices.

The Key Differences Between Bonding and Grounding

You should comprehend that bonding and grounding serve different purposes in electrical systems. Bonding creates a conductive path to guarantee safety and prevent shock, while grounding directs excess electricity safely into the earth. Their connection methods also differ, with bonding often involving metal-to-metal links and grounding using specific grounding electrodes. Additionally, the increasing use of advanced safety systems underscores the importance of proper grounding and bonding practices in modern electrical installations.

Purpose and Function

While bonding and grounding both play vital roles in electrical safety, they serve distinct purposes that set them apart. Bonding ensures conductive parts are connected to prevent potential differences, reducing shock risk. Grounding provides a path for fault current to safely reach the earth, triggering protective devices. Their functions can be summarized as follows:

| Purpose | Function | Key Benefit |

|---|---|---|

| Bonding | Connects metal parts to equalize voltage | Prevents electric shock |

| Grounding | Connects system to earth for fault path | Facilitates circuit protection |

| Overall Safety | Minimizes electrical hazards | Protects lives and equipment |

Understanding these roles helps you recognize how each component contributes to electrical safety and life-saving measures. Proper grounding techniques are essential for ensuring that protective devices operate correctly during faults.

Connection Methods

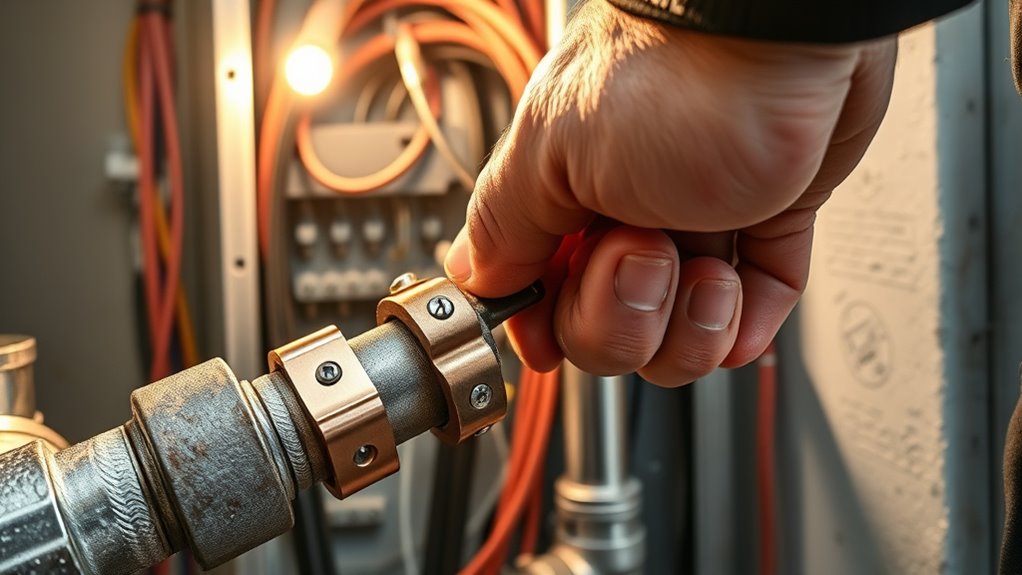

Bonding and grounding differ markedly in how they establish electrical connections. Bonding connects metallic parts to create a continuous conductive path, guaranteeing they stay at the same electrical potential. You typically use bonding jumpers or wires to link parts like metal enclosures, pipes, and equipment. This prevents voltage differences that could cause sparks or shocks. Grounding, on the other hand, connects electrical systems to the earth through grounding electrodes, such as rods or plates. This provides a safe path for fault currents to dissipate into the ground, reducing shock hazards. While bonding ties conductive parts together, grounding links the system to the earth. Both methods are vital, but they serve distinct purposes and use different connection techniques to ensure safety. Additionally, understanding the types of ice cream and their ingredient differences can help ensure the safety and quality of the materials used in electrical components, especially in environments where dairy-based products are stored or processed.

How Bonding Prevents Electrical Shock Hazards

Bonding plays an essential role in preventing electrical shock hazards by creating a low-resistance path for fault currents to safely flow into the ground. When a metal part becomes energized due to a fault, bonding ensures that it remains at the same potential as the ground, preventing a dangerous voltage difference. This minimizes the risk of electric shock if you touch the metal surface. Without proper bonding, a fault current could cause the metal part to become live, increasing the chance of severe shock or electrocution. Bonding effectively directs any unintended current away from you and toward the ground, reducing the danger. By maintaining a continuous, low-resistance connection between conductive parts, bonding acts as a critical safety measure to protect you from electrical shock hazards. Additionally, understanding grounding methods enhances overall electrical safety and helps prevent accidents.

The Importance of Proper Grounding in Electrical Systems

Proper grounding is essential for ensuring electrical safety and system reliability. It provides a safe path for fault currents, preventing electric shocks and equipment damage. When grounding is done correctly, it helps protect you and your property from electrical hazards. To understand its importance better, consider these points:

- Protects Lives: Proper grounding minimizes the risk of electric shock during faults.

- Prevents Damage: It reduces potential damage to electrical devices caused by surges.

- Ensures System Stability: Proper grounding maintains voltage levels, ensuring consistent operation.

- Facilitates Fault Detection: It makes troubleshooting easier by providing clear fault paths.

– Additionally, proper grounding practices can help mitigate electrical hazards associated with improper connections and prevent unintended current flows that could lead to fires or injury.

Skipping proper grounding can lead to dangerous situations, equipment failure, and costly repairs. Always prioritize correct grounding practices for safety and system integrity.

Common Applications of Bonding and Grounding

Have you ever wondered where bonding and grounding are most commonly used? You’ll find these practices in residential, commercial, and industrial settings. In homes, grounding protects your appliances and prevents electrical shock hazards. Bonding is used to connect metal parts, ensuring they stay at the same electrical potential. In commercial buildings, grounding systems help manage lightning strikes and electrical faults, safeguarding equipment and occupants. Industrial facilities rely heavily on bonding and grounding to control static electricity and protect sensitive machinery. Electrical panels, pipelines, and metal enclosures are common points where bonding connects all conductive parts. These applications work together to create a safe environment, preventing dangerous voltage build-ups and ensuring that electrical systems function reliably. Understanding the importance of pinball machine weights can also be crucial when installing large equipment, ensuring safety and proper setup.

Potential Risks of Misusing Bonding and Grounding

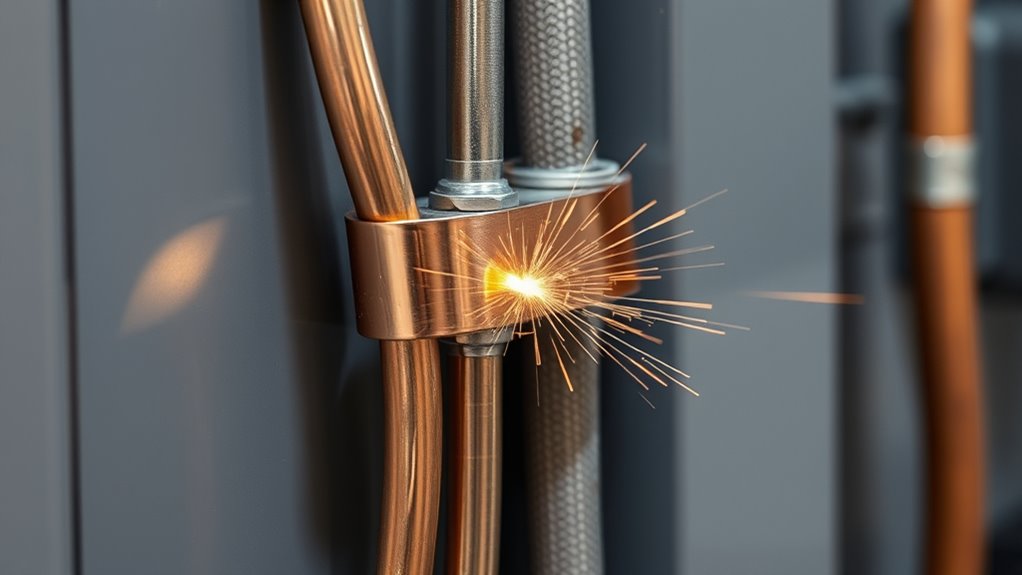

While the correct use of bonding and grounding systems promotes safety, improper application can introduce serious risks. Misusing these systems might lead to dangerous situations that threaten your safety and equipment.

A misconnection or poor maintenance can also result in industry trends that are hard to detect until damage occurs.

Codes and Standards Governing Bonding and Grounding

To guarantee safety and reliability, bonding and grounding systems must conform to established codes and standards. These regulations, such as the National Electrical Code (NEC) and IEEE standards, specify proper materials, connection methods, and installation procedures. They ensure your systems effectively prevent electrical shock, protect equipment, and reduce fire risks. Familiarize yourself with local, national, and industry-specific requirements, as they can vary. Compliance with these standards isn’t optional — it’s essential for safety and legal approval. Regular inspections and updates are also critical to maintain adherence. By following these codes, you ensure your bonding and grounding systems perform correctly, minimizing hazards and maximizing protection in all electrical installations. Understanding juice cleansing can also highlight the importance of adhering to proper safety protocols in health-related practices.

Real-Life Incidents Highlighting the Need for Proper Bonding and Grounding

Real-life incidents underscore the importance of proper bonding and grounding by demonstrating the potentially severe consequences of neglecting these systems. You see, when systems aren’t properly bonded or grounded, the risk of electrical shocks, fires, or equipment damage skyrockets. For example:

- A worker received a fatal electric shock because a metal tool contacted ungrounded equipment.

- An electrical fire broke out in a warehouse due to improper grounding of wiring.

- A household appliance caused a shock because it wasn’t properly bonded to the system.

- Power surges damaged sensitive electronics because grounding systems failed during a storm.

These incidents highlight how neglecting bonding and grounding endangers lives and property. Proper systems could prevent such tragedies, emphasizing why adherence to safety standards is non-negotiable.

Best Practices for Ensuring Safety Through Bonding and Grounding

Ensuring safety through proper bonding and grounding requires following established best practices that minimize risks and protect people and equipment. First, always use appropriately rated materials that meet local electrical codes. Regularly inspect connections to ensure they are tight, corrosion-free, and intact. Keep grounding and bonding conductors short and direct, avoiding unnecessary loops or bends that can cause faults. Properly label all grounding points for easy identification during maintenance. Maintain a clean, dry environment around grounding connections to prevent corrosion. Use approved connectors and clamps for reliable connections. Follow manufacturer instructions and adhere to electrical standards for installation and testing. Lastly, conduct routine testing and inspections to confirm effective grounding and bonding, ensuring ongoing safety and compliance.

Frequently Asked Questions

Can Improper Bonding or Grounding Cause Electrical Fires?

Yes, improper bonding or grounding can cause electrical fires. When bonding isn’t done correctly, it creates potential differences that can lead to sparks or arcing. Similarly, inadequate grounding fails to safely direct fault currents away from equipment, increasing the risk of overheating and fires. You need to guarantee proper bonding and grounding to protect your home or workplace from electrical hazards and prevent fires.

How Often Should Bonding and Grounding Systems Be Inspected?

You should inspect your bonding and grounding systems at least once a year to guarantee safety and proper function. Regular inspections help identify corrosion, loose connections, or damage that could compromise the system. If your environment is harsh or your system is critical, consider more frequent checks. Always hire a qualified electrician to perform thorough inspections, and keep detailed records to maintain ongoing safety standards.

What Are the Signs of a Faulty Electrical Bonding Connection?

You’ll notice a faulty electrical bonding connection if there’s visible corrosion, discoloration, or loose fittings. You might also experience electrical shocks when touching appliances or metal parts near electrical systems. Inconsistent grounding or frequent tripping of circuit breakers can signal issues. Regular inspections are vital because these signs can be subtle, and addressing them promptly helps prevent dangerous electrical failures and potential injuries.

Are There Specific Tools Required for Testing Bonding and Grounding?

Yes, you need specific tools to test bonding and grounding. A multimeter or a clamp meter is essential for measuring resistance and verifying connections. You might also use a ground tester or an Earth ground tester to guarantee proper grounding. These tools help you accurately assess if the bonding and grounding systems are functioning correctly, ensuring safety and compliance with electrical codes. Always follow manufacturer instructions and safety guidelines when testing.

How Do Environmental Factors Affect Bonding and Grounding Effectiveness?

Environmental factors like moisture, temperature, and corrosion markedly impact bonding and grounding effectiveness. Moisture can cause corrosion or increase resistance, while extreme temperatures may weaken connections or degrade materials over time. Corrosive environments accelerate deterioration, reducing conductivity. You should regularly inspect and maintain grounding and bonding systems, especially in harsh conditions, to guarantee they remain effective and safe, preventing electrical hazards and ensuring reliable system performance.

Conclusion

Remember, just like Icarus needed the wings to soar safely, proper bonding and grounding keep you protected from electrical disasters. By understanding their roles and following safety standards, you guarantee your system won’t fall like Icarus did, crashing due to neglect. Stay vigilant, prioritize safety, and treat bonding and grounding as your wings—essential for a secure and shock-free environment. Don’t take chances; your safety depends on it.