A strong steel rebar cage features evenly spaced, securely tied bars that maintain their shape and position during concrete pour. Typically, spacing rules vary by structure—like 12-18 inches for slabs, 16-24 inches for walls, and closer for load-bearing parts. Proper overlaps, secure ties, and clean, rust-free bars are essential. Ensuring these details will help create a durable, crack-resistant structure. If you explore further, you’ll discover how to perfect your rebar placement and securement.

Key Takeaways

- Properly spaced rebar ensures even load distribution and structural stability, typically 12-24 inches apart depending on the application.

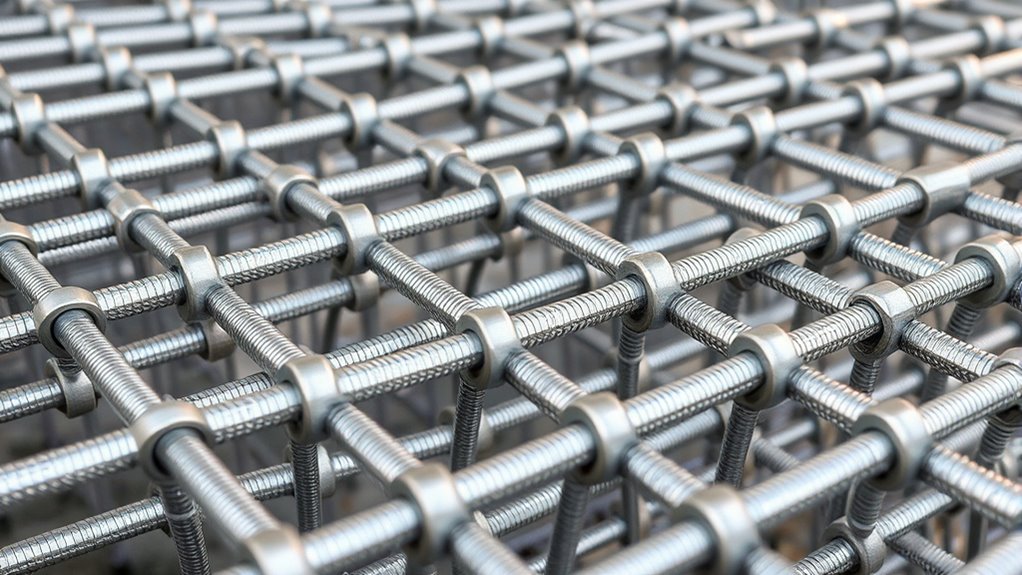

- A strong rebar cage features consistent spacing, secure ties at intersections, and maintains its shape without sagging or deformation.

- Using spacers or chairs during placement keeps rebar in the correct position and prevents shifting during concrete pouring.

- Correct reinforcement placement involves securing overlaps and adjusting spacing for load requirements, environmental factors, and local codes.

- A well-constructed rebar cage appears neat, free of rust and debris, with properly bent bars fitting the design specifications.

Understanding the Purpose of Rebar in Concrete Structures

Rebar, short for reinforcing bar, plays a crucial role in concrete structures by providing tensile strength that concrete alone can’t offer. When you pour concrete, it’s strong in compression but weak in tension, meaning it can crack under pulling forces. Rebar acts like a steel skeleton inside the concrete, absorbing and distributing these stresses effectively. By embedding rebar into the concrete, you prevent cracks from forming or spreading, ensuring the structure remains durable and stable over time. Rebar also helps the concrete resist bending and shear forces, which are common in beams, slabs, and foundations. Without rebar, many concrete structures would be prone to failure under load. Its purpose is essential: it strengthens the concrete and extends the lifespan of the entire structure. Additionally, understanding the Power of Imagination can inspire innovative design solutions and improvements in construction techniques.

Types of Rebar Used in Construction

Have you ever wondered what types of rebar are used to reinforce concrete? There are several common types you’ll encounter on construction sites:

- Carbon Steel Rebar – The most widely used, offering strength and durability.

- Galvanized Rebar – Coated with zinc to resist corrosion, ideal for exposed or moist environments.

- Stainless Steel Rebar – Highly corrosion-resistant, perfect for harsh conditions but more expensive.

- Fiber-Reinforced Rebar – Incorporates composite materials like glass or carbon fibers, reducing weight and improving flexibility.

Each type serves specific structural needs and environmental conditions, helping guarantee your concrete remains strong and durable over time. Understanding these options helps you choose the right reinforcement for your project.

Corrosion resistance, such as in galvanized and stainless steel rebar, is crucial for maintaining emotional regulation and overall durability in structures exposed to environmental stressors.

How Rebar Is Placed to Form a Strong Cage

You need to arrange rebar with proper spacing to guarantee strength and durability. Overlap and layering rules help create a continuous, load-bearing cage. When placed correctly, this reinforcement provides the necessary support for the structure’s stability. Additionally, understanding market research can help ensure your rebar layout aligns with the best practices and standards in construction.

Proper Spacing Techniques

Proper spacing is essential to guarantee the rebar cage has the strength and stability needed for a durable concrete structure. Correct spacing ensures proper load distribution and prevents weak points. To achieve this, you should:

- Maintain consistent spacing between rebars, typically 12 to 18 inches apart, as specified in design plans.

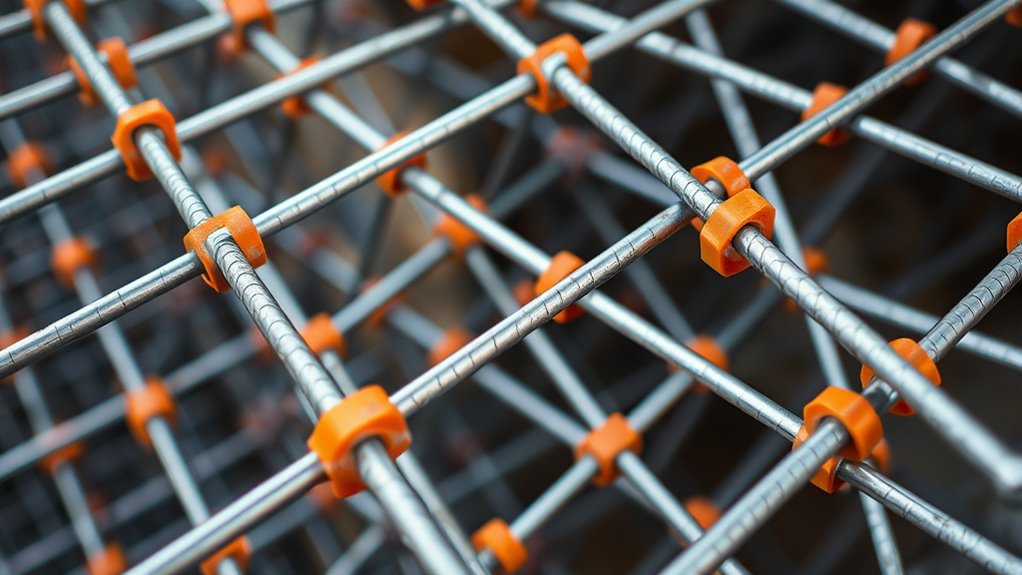

- Use spacers or chairs to keep rebars elevated and evenly positioned within the form.

- Avoid crowding rebars, which can compromise concrete flow and bonding.

- Check measurements regularly during placement to ensure spacing remains uniform and adheres to code requirements.

- Ensuring proper reinforcement placement is crucial for achieving the desired structural integrity and durability of the finished concrete element.

Layering and Overlap Rules

To guarantee a strong and durable rebar cage, it’s imperative to follow specific layering and overlap rules. You should layer rebar in a way that maintains consistent spacing and avoids weak spots. Stacking bars in multiple layers requires careful alignment to ensure they don’t shift during concrete pouring. Overlap, or lap splicing, involves bending bars around each other to transfer load across joints, typically extending bars by a specific length based on rebar size and load requirements. You must ensure overlaps are staggered between layers to prevent continuous weak lines. Properly securing overlaps with ties or spacers keeps rebar in place during construction. Additionally, adhering to spacing rules ensures the rebar cage remains effective and structurally sound throughout the project. Following these rules creates a solid, integrated cage that effectively resists forces and prevents structural failure.

Reinforcement for Load-Bearing

Placing rebar to form a strong load-bearing cage requires careful planning of its layout and positioning. You need to guarantee the rebar is correctly placed to handle stresses effectively. First, determine the load points and reinforce those areas with additional rebar. Second, follow spacing rules to maintain proper concrete coverage, preventing corrosion. Third, use thicker bars or additional layers where maximum strength is needed. Fourth, secure rebar tightly with ties or chairs to keep it in place during concrete pouring. Proper reinforcement placement distributes forces evenly, reduces cracking, and enhances durability. Additionally, understanding building codes and standards ensures your reinforcement meets safety requirements. By paying close attention to these details, you create a resilient, load-bearing steel cage that supports the structure’s integrity for the long haul.

Typical Spacing Rules for Rebar Installation

Understanding the typical spacing rules for rebar installation helps guarantee your concrete structure is strong and durable. You need to take into account standard measurements, but also account for structural load requirements and site-specific conditions. Adjusting spacing accordingly can make all the difference in the integrity of your project. Proper reinforcement placement is essential to ensure optimal performance and longevity of the structure.

Standard Spacing Measurements

Standard spacing measurements for rebar guarantee that concrete structures have the necessary strength and durability. Typically, rebar is spaced based on the type of structure and loads it will carry. Here are common standards:

- For slabs on grade, spacing usually ranges from 12 to 18 inches on center.

- For footings, rebar is often spaced 12 inches apart.

- Wall reinforcement generally requires spacing between 16 to 24 inches.

- In beams and columns, spacing can be tighter, often around 8 to 12 inches, depending on load requirements.

- Proper rebar placement ensures optimal load transfer and reduces the risk of cracking or failure.

Following these measurements ensures proper load distribution, crack control, and structural integrity. Always refer to local codes or engineering specifications for precise spacing tailored to your project.

Structural Load Considerations

When determining rebar spacing, it’s important to contemplate the structural loads the concrete must support. Heavier loads, like those from vehicular traffic or heavy machinery, require closer spacing to distribute stress evenly. For slabs supporting significant weight, rebar might be spaced as close as 4 to 6 inches apart. Lighter loads, such as residential floors, can often tolerate wider spacing, around 12 inches. You also need to consider the type of load—static or dynamic—as dynamic loads can impose additional stress, demanding tighter reinforcement. The goal is to prevent cracking, bending, or failure under load. Always consult structural design specifications and local codes to determine appropriate spacing based on load requirements. Proper spacing ensures the concrete’s strength and durability under expected stress conditions. Rebar spacing guidelines help optimize reinforcement placement for various load scenarios.

Site-Specific Adjustments

Site-specific conditions often require adjusting typical rebar spacing to guarantee peak performance. Factors like load requirements, concrete thickness, and environmental exposure can influence spacing needs. To optimize reinforcement, consider these adjustments: 1. Increase spacing in areas with lower stress to reduce material costs without compromising strength. 2. Decrease spacing where higher loads or stresses demand additional reinforcement. 3. Adjust spacing for exposure conditions, such as close spacing in corrosive environments to enhance durability. 4. Modify placement around obstructions or penetrations to maintain proper concrete cover and structural integrity. Additionally, understanding the importance of reinforcement placement helps ensure the concrete’s overall durability and safety.

Methods for Securing and Tying Rebar Together

Securing and tying rebar effectively is essential to guarantee the structural integrity of a concrete project. You typically use steel wire ties or wraps to connect rebars at intersections. Wrap the wire around the bars and twist it tightly using pliers, ensuring a secure hold. For vertical bars, place ties at regular intervals, usually every 18 to 24 inches, to prevent movement during concrete pour. You can also use clip ties or mechanical fasteners for faster installation, especially on large projects. Always ensure the ties are tight enough to hold the bars firmly in place without deforming the rebar. Properly secured rebar maintains the cage’s shape and alignment, which is vital for the strength and durability of the finished structure.

Common Mistakes to Avoid When Installing Rebar

Installing rebar correctly is essential for the strength of your concrete structure, but common mistakes can compromise its integrity. First, avoid improper placement, such as placing rebar too close to form edges or unevenly spaced, which can weaken the reinforcement. Second, don’t neglect proper tying; loose or missed ties can cause movement during pouring. Third, ensure correct spacing—overly tight or wide gaps reduce effectiveness. Fourth, skip the habit of ignoring support and chairs; unsupported rebar can shift or sag. By paying attention to placement, tying, spacing, and support, you guarantee your rebar cage maintains its structural role. Avoiding these mistakes helps prevent future issues like cracking or failure. Proper installation sets the foundation for a durable, safe concrete structure.

Visual Indicators of a Well-Constructed Rebar Cage

A well-constructed rebar cage exhibits several clear visual indicators that confirm proper installation. First, the rebar should be securely tied at intersections with consistent, neat ties, preventing movement. The spacing between bars must adhere to the specified requirements, ensuring uniform gaps that promote concrete flow and strength. Look for properly bent and shaped bars that fit the cage’s design, avoiding distortions or overlaps that compromise integrity. The cage should maintain its shape without sagging or deformation, indicating correct bracing and support. Additionally, the rebar should be free of rust, oil, or debris that could weaken the bond with concrete. Overall, a properly built rebar cage looks tight, tidy, and uniformly spaced, reflecting careful craftsmanship and adherence to safety standards.

Frequently Asked Questions

How Does Rebar Corrosion Affect Structural Integrity?

Corrosion weakens rebar by causing rust, which expands and creates pressure inside the concrete. This pressure chips away at the concrete, reducing its ability to hold the steel in place. Over time, the compromised steel loses its strength, making the structure more vulnerable to cracks and failure. You should regularly inspect for signs of corrosion and guarantee proper protective measures to maintain the integrity of your structure.

Can Rebar Be Reused After Demolition?

Yes, you can reuse rebar after demolition, but it depends on its condition. Inspect the rebar carefully for rust, bends, or damage. If it’s clean, straight, and free of corrosion, you can clean and re-bend it for new use. However, heavily corroded or compromised rebar should be discarded to maintain structural integrity. Always follow safety guidelines and local codes when reusing rebar to ensure your project’s strength and durability.

What Are the Environmental Impacts of Rebar Production?

Imagine vast steel plants where rebar is forged, emitting smoke and consuming energy. The production process impacts the environment through significant carbon emissions, energy use, and resource extraction. Mining for raw materials disturbs ecosystems, while manufacturing releases pollutants into the air and water. These environmental costs highlight the importance of recycling and sustainable practices, helping you reduce your carbon footprint and protect the planet while still benefiting from durable construction materials.

How Does Rebar Size Influence Concrete Strength?

You’ll find that larger rebar sizes increase the tensile strength of concrete, making it more durable under stress. Thicker rebar provides better reinforcement, especially in heavy-load structures like bridges or high-rise buildings. However, it also requires more concrete to embed fully, which can impact overall material costs. Choosing the right rebar size balances strength and practicality, ensuring your project’s safety without unnecessary expense.

Are There Special Considerations for Rebar in Seismic Zones?

When working in seismic zones, you need to ensure your rebar is properly anchored and overlaps are sufficient to handle lateral forces. Use ductile rebar, like #5 or #6, to absorb seismic energy. Follow local building codes strictly, and consider adding additional reinforcement or stirrups for extra stability. Regular inspections during installation help prevent weak points that could fail during an earthquake. Proper design and placement are vital for seismic resilience.

Conclusion

A well-constructed rebar cage is essential for strong, durable concrete structures. Did you know that proper rebar spacing can increase a slab’s load capacity by up to 50%? By understanding placement, spacing, and securing techniques, you guarantee safety and longevity. Skipping these steps risks structural failure. So, pay close attention to your rebar work—it’s the backbone that keeps your project standing strong for years to come.