If your pump starts to squeal or make loud banging noises, it’s likely a sign of cavitation, which causes vapor bubbles to form and collapse, damaging the impeller. These sounds often indicate high vibrations, flow issues, and reduced efficiency, threatening your pump’s lifespan. Ignoring these signs can lead to costly failures. To protect your equipment, it’s essential to understand what these noises mean and how to address them—more tips ahead can help you prevent serious damage.

Key Takeaways

- Squealing or high-pitched noises often indicate cavitation caused by vapor bubble collapse.

- Unusual vibrations and fluctuating pressure signal cavitation or mechanical issues.

- Persistent loud pump noise can lead to impeller damage and reduced lifespan.

- Cavitation occurs when inlet pressure drops below vapor pressure, causing damaging vapor bubbles.

- Early detection of abnormal sounds helps prevent costly repairs and extends pump operational life.

Understanding Pump Noise: Normal vs. Abnormal Sounds

Understanding pump noise involves recognizing the difference between normal and abnormal sounds. When your pump operates smoothly, it produces a steady hum or gentle vibration, which is standard. You might hear a consistent, low-frequency noise that indicates proper functioning. However, abnormal sounds often stand out—such as high-pitched squeals, grinding noises, or banging. These sounds can signal issues like cavitation, air leaks, or mechanical wear. Pay attention to changes in volume or pitch, especially if noises become louder or more irregular. Regularly listening to your pump helps you identify these differences early. Spotting normal sounds from abnormal ones allows you to act promptly, preventing further damage or failure. Trust your ears; they’re essential for maintaining optimal pump performance. Additionally, understanding how cavitation occurs can help you diagnose and address these troubling noises more effectively.

What Is Cavitation and How Does It Occur?

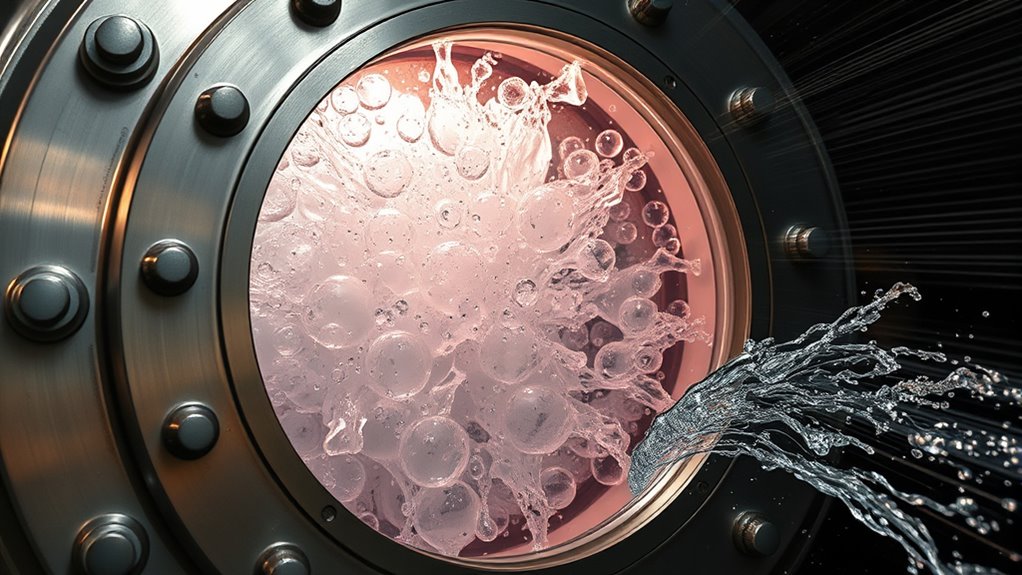

Cavitation occurs when vapor bubbles form in a pump’s fluid due to local drops in pressure below the liquid’s vapor pressure. This happens when the fluid velocity increases or there’s a sudden change in flow direction, causing pressure to drop. As the pressure dips below vapor pressure, tiny vapor bubbles develop. These bubbles are harmless on their own, but when they move to higher-pressure areas within the pump, they collapse violently. The implosion of these bubbles releases energy that can damage pump components and generate noise. Cavitation often starts at the pump inlet or around impeller blades, where pressure variations are most intense. Recognizing how cavitation begins helps you understand why your pump might be making strange noises or showing signs of wear. Additionally, noise levels can serve as an indicator of cavitation, alerting you to potential issues before significant damage occurs.

Identifying the Signs of Cavitation in Your Pump

You’ll notice your pump making strange noises or vibrating more than usual, which can be early signs of cavitation. A sudden drop in flow rate also indicates something’s wrong inside the pump. Recognizing these signs quickly helps prevent further damage and costly repairs.

Unusual Pump Noises

Unusual noises from your pump can be a clear sign that cavitation is occurring. You might hear high-pitched squealing, grinding, or rattling sounds that aren’t typical during normal operation. These sounds often result from vapor bubbles collapsing near the impeller blades, creating shockwaves that generate noise. If you notice a sudden change in the pitch or intensity of the pump’s sound, it’s likely cavitation starting. Sometimes, the noise may seem intermittent or vary with flow rate adjustments. Pay attention to these auditory cues, as they often precede more serious damage. Recognizing these signs early lets you take corrective action before cavitation causes significant wear or failure. Trust your ears—unusual pump noises are telling you something’s wrong. Additionally, being aware of dog names can help you personalize your pump maintenance routine or create a memorable troubleshooting checklist.

Vibration and Shaking

When cavitation occurs, it often causes your pump to vibrate excessively and shake more than usual. You might feel it through sudden, intense tremors in the equipment, making you uneasy about its condition. This shaking isn’t normal—it signals something’s wrong beneath the surface. Recognizing this sign early can prevent costly damage and downtime.

| Vibration Signs | Emotional Impact |

|---|---|

| Unsteady, irregular movements | Creates anxiety about potential failure |

| Loud, banging sounds | Sparks fear of catastrophic damage |

| Sudden jolts during operation | Generates panic over safety risks |

| Persistent shaking | Fuels concern about repair costs |

| Unusual noise accompanied by shake | Triggers urgency to inspect immediately |

Decreased Flow Rate

A noticeable decrease in flow rate is often one of the earliest indicators that cavitation is affecting your pump. When cavitation occurs, vapor bubbles form and collapse within the impeller, disrupting the smooth flow of liquid. As this damage progresses, your pump can’t deliver the same volume it used to, leading to a drop in flow rate. You might notice that despite the pump running at the same speed, less fluid is being pumped through the system. This reduction can cause downstream equipment to underperform or even shut down. If you observe a sudden or gradual decrease in flow rate, it’s essential to investigate further. Recognizing vapor bubble formation is crucial for diagnosing cavitation early before more severe damage occurs. Ignoring this sign can lead to more severe damage and costly repairs down the line.

The Impact of Cavitation on Pump Performance and Longevity

Cavitation can markedly reduce your pump’s efficiency, making it work harder and less effectively. Over time, it accelerates wear and tear on components, leading to costly repairs. If left unchecked, cavitation shortens the overall lifespan of your equipment, impacting your operations. Recognizing signs like pump noise early can help prevent further damage and ensure optimal performance.

Reduced Pump Efficiency

Cavitation causing bubble formation and collapse inside a pump reduces its efficiency by disrupting the flow of fluid and increasing internal vibrations. These bubbles temporarily block the flow path, forcing the pump to work harder to move the same amount of fluid. As a result, your pump consumes more energy, lowering overall performance. The constant collapse of bubbles also damages impellers and other components, creating turbulence that prevents smooth operation. Over time, this leads to decreased flow rates and pressure, making your system less effective. You’ll notice increased energy bills and reduced output, both signs that cavitation is compromising your pump’s efficiency. Addressing cavitation early helps maintain ideal performance, saving you money and preventing further damage. Recognizing the signs of a failing pump early on can help prevent costly repairs and extend the lifespan of your equipment.

Accelerated Wear and Tear

Since cavitation causes bubbles to collapse violently inside your pump, it accelerates wear on essential components like impellers and bearings. The intense shockwaves from bubble collapse create micro-cracks and surface pitting, weakening these parts over time. This increased stress leads to faster deterioration, reducing the pump’s overall reliability. As wear progresses, you may notice increased vibration or abnormal noise, signaling that components are degrading. Cavitation also causes misalignment and imbalance, further stressing your pump’s internal parts. The repeated impact shortens the lifespan of key elements, forcing you to replace or repair them more frequently. Additionally, cavitation can lead to vibration issues and reduce overall efficiency, which further contributes to premature failure. Over time, this accelerated wear hampers your pump’s ability to operate smoothly, demanding costly maintenance and risking unexpected breakdowns if left unaddressed.

Shortened Equipment Lifespan

The damage caused by cavitation doesn’t just compromise your pump’s immediate performance; it also considerably shortens its overall lifespan. When cavitation occurs, the imploding bubbles create shockwaves that erode impellers, seals, and other essential components. Over time, this erosion weakens the pump’s structural integrity, leading to increased failures and costly repairs. Continuous exposure to cavitation accelerates metal fatigue, causing parts to crack or break prematurely. As your pump struggles to operate efficiently, you may notice more frequent downtime and higher maintenance costs. Recognizing cavitation early and addressing it promptly can help preserve your pump’s longevity and avoid costly replacements. Resources and Tools can provide additional guidance on maintaining pump performance and preventing issues caused by cavitation.

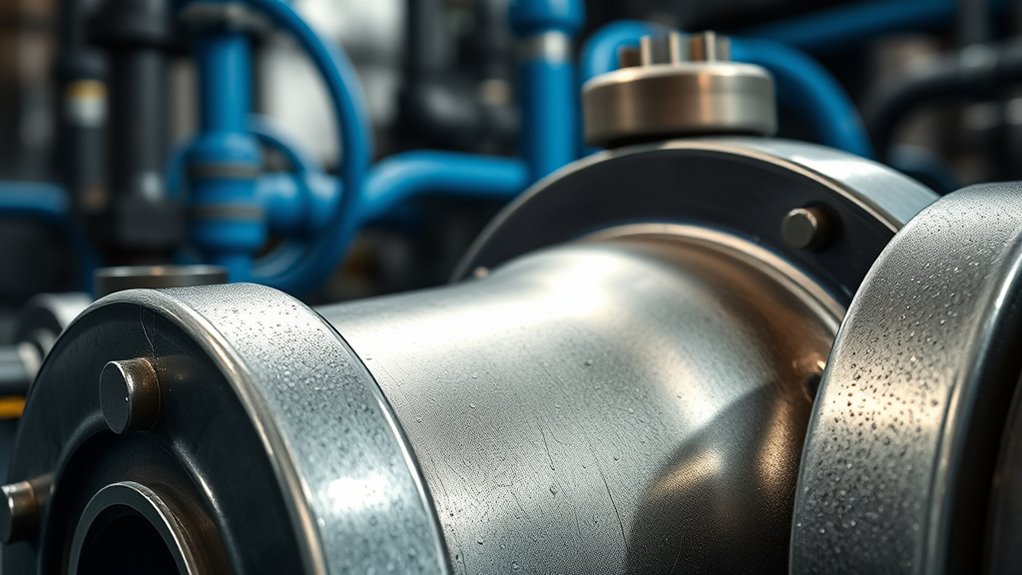

Common Causes of Pump Noise and Vibrations

Many common issues can cause pump noise and vibrations, often stemming from mechanical or operational problems. Loose or misaligned components, such as couplings, impellers, or bearings, can create imbalance and rattling sounds. Worn or damaged bearings produce grinding or humming noises and increase vibrations. Cavitation, caused by insufficient inlet pressure, leads to banging and knocking sounds. Excessive pump speed or improper installation can also cause vibrations due to mechanical stress. Additionally, debris or foreign objects inside the pump can create uneven flow and noise. Poor foundation or mounting can amplify vibrations, affecting the entire system. Regular maintenance and inspection are key to catching these common causes before they escalate. Properly addressing hydro-kinetic forces can prevent many of these issues and prolong the lifespan of your pump.

How to Diagnose a Screaming Pump

When your pump starts screaming, it’s vital to recognize the signs of cavitation, like unusual vibrations or inconsistent sounds. Pay close attention to the noise and how the pump vibrates, as these clues can point to specific issues. Identifying these symptoms early helps you determine if cavitation is the culprit. Additionally, understanding the signs of spoilage in fluids can help diagnose underlying problems with the pump’s operation.

Signs of Cavitation

A loud, screaming noise from your pump is a clear sign that cavitation may be occurring. You might notice this noise during operation, especially when the flow rate drops or the pump struggles to maintain pressure. Cavitation causes the impeller blades to vibrate violently, creating high-frequency sounds that resemble screaming or whining. Alongside noise, you may observe fluctuating pressure readings or a drop in flow efficiency. The pump may also vibrate excessively or show signs of early wear on bearings and impeller blades. If you see these signs, it’s essential to investigate further. Ignoring them can lead to severe damage, costly repairs, or complete pump failure. Recognizing these symptoms early helps you take corrective action before cavitation causes irreparable harm.

Sound and Vibration Clues

Screaming or high-pitched noises from your pump are clear indicators that cavitation may be present, and recognizing these sounds quickly can save you from costly damage. When your pump emits these sharp, whining noises, it’s a sign that vapor bubbles are forming and collapsing, disrupting normal operation. Pay attention to vibration patterns too, as excessive shaking often accompanies cavitation.

You can diagnose a screaming pump by noting these clues:

- Sudden increase in noise level

- Whining or squealing sounds during operation

- Unusual vibrations or shaking

- Changes in flow or pressure performance

Addressing these cues early helps prevent damage and keeps your pump running smoothly. Never ignore strange sounds—your pump’s noise is telling you something’s wrong.

Preventing Cavitation and Reducing Noise

To effectively prevent cavitation and reduce pump noise, you need to focus on enhancing operating conditions and maintaining proper system design. Confirming the pump operates within its recommended flow rate and pressure ranges minimizes cavitation risk. Keep suction conditions stable by avoiding excessive head loss or pipe restrictions. Properly sizing pipes and components reduces turbulence that can cause noise. Regular maintenance, such as inspecting for wear and leaks, helps sustain ideal performance. Use the table below to identify key factors:

| Operating Condition | System Design Strategy |

|---|---|

| Maintain proper flow | Use correctly sized piping |

| Control pressure | Install pressure relief valves |

| Avoid sudden changes | Ensure gradual flow transitions |

Troubleshooting Tips for Noisy Pump Operations

When your pump operates noisily, quick identification of the cause can prevent further damage and improve system performance. Start by checking for cavitation signs, such as vibration or banging sounds. Verify the pump isn’t running dry or with insufficient suction. Confirm that the inlet pipe isn’t clogged, kinked, or leaking air. Also, validate that the pump isn’t operating beyond its recommended flow or head limits, which can cause turbulence.

- Inspect for air leaks or leaks in the inlet piping

- Confirm proper pump alignment and mounting

- Check for worn or damaged impellers

- Monitor flow rates and system pressure

Addressing these issues early helps reduce noise, extend pump life, and maintain efficient operation.

When to Seek Professional Assistance

While some pump noise issues can be resolved through troubleshooting, there are times when professional assistance becomes essential. If you notice persistent or worsening noise despite your efforts, it’s a clear sign you need expert help. Sudden increases in noise levels, especially if accompanied by vibrations or leaks, indicate serious problems like cavitation damage or bearing failure. Additionally, if your pump isn’t operating within recommended parameters or if it’s overheating, professionals can diagnose underlying issues accurately. Attempting repairs beyond basic fixes can risk further damage or safety hazards. When in doubt, consult a qualified technician to perform detailed inspections and repairs, ensuring your pump gets back to ideal performance without risking costly breakdowns or safety issues.

Maintaining Your Pump to Avoid Future Problems

Regular maintenance is key to preventing pump problems before they start. By staying proactive, you can catch issues early and keep your pump running smoothly. Regularly inspect for leaks, corrosion, and wear on seals and bearings. Keep an eye on vibration levels and listen for unusual noises, which can signal trouble. Ensure the pump is properly lubricated and that the motor is clean and free of dust. Check the alignment and tighten fittings if needed to prevent stress on components. Schedule routine checks and replace worn parts promptly. Staying attentive to these details helps avoid cavitation, noise, and costly repairs down the line. Remember, consistent upkeep prolongs your pump’s lifespan and keeps your system operating efficiently.

Frequently Asked Questions

Can Pump Noise Indicate Electrical Issues Besides Cavitation?

Yes, pump noise can signal electrical issues beyond cavitation. If you hear unusual or loud sounds, it might be due to motor problems, worn brushes, or electrical imbalances. These issues cause vibrations or irregular motor operation, resulting in noise. Regularly inspect your pump’s electrical connections and motor components to catch potential problems early, preventing costly damage and ensuring smooth, quiet operation.

How Does Fluid Temperature Affect Cavitation Risk?

Higher fluid temperatures increase cavitation risk because warm fluid lowers the vapor pressure, making it easier for bubbles to form within the pump. As temperature rises, the fluid vaporizes more readily at lower pressures, leading to cavitation. To prevent this, you should monitor fluid temperatures closely, ensure proper pump operation, and consider cooling systems if necessary. Maintaining ideal temperature levels helps reduce cavitation and prolongs your pump’s lifespan.

Are Certain Pump Types More Prone to Cavitation?

Yes, certain pump types are more prone to cavitation. You’ll find that centrifugal pumps, especially those operating near their maximum flow or at high speeds, are more vulnerable. Axial and mixed-flow pumps can also experience cavitation if not properly maintained or if the system isn’t correctly designed. To minimize risks, verify your pump operates within its specified parameters, maintains adequate inlet pressure, and avoids sudden flow changes.

What Are the Long-Term Effects of Silent Cavitation?

Silent cavitation can cause long-term damage to your pump by eroding impeller surfaces and weakening seals over time. This gradual wear reduces efficiency, increases energy consumption, and can lead to costly repairs or replacements. If you ignore silent cavitation, you’re risking decreased pump lifespan and potential system failures. Regular maintenance and monitoring are essential to identify early signs, preventing serious damage and ensuring your pump operates reliably for years to come.

Can Noise Levels Help Predict Impending Pump Failure?

Yes, noise levels can help predict impending pump failure. You should pay close attention to unusual sounds, like screaming or knocking, as they often indicate cavitation or bearing issues. Consistent monitoring allows you to identify these early warning signs, so you can perform maintenance before catastrophic failure occurs. Regularly analyzing noise patterns guarantees you catch problems early, saving you money and avoiding costly downtime.

Conclusion

Think of your pump as a delicate orchestra conductor—when it’s humming smoothly, everything flows in harmony. But when cavitation strikes, it’s like discordant notes disrupting the symphony. By understanding and addressing these issues, you keep your pump’s performance in tune, ensuring longevity and efficiency. Remember, early detection is your baton—guiding you to restore harmony before chaos takes center stage. Keep listening, stay attentive, and your pump will sing its song for years to come.