Hydrostatic relief valves are small but essential parts that protect your equipment’s shell from dangerous pressure buildup. They work by continuously monitoring system pressure and opening automatically when limits are exceeded, allowing excess fluid to escape and prevent damage. Choosing the right relief valve guarantees your system stays safe, reliable, and lasts longer. To keep everything running smoothly and discover how this affordable part can save you big, keep exploring.

Key Takeaways

- Hydrostatic relief valves prevent overpressure damage, protecting your equipment and extending its lifespan.

- They automatically open to release excess pressure, ensuring system safety during overload conditions.

- Proper installation and regular maintenance of these valves safeguard system reliability and performance.

- Replacing worn or faulty relief valves, often costing around $30, is a cost-effective way to prevent costly repairs.

- Ensuring the relief valve functions correctly is crucial for maintaining safety and avoiding equipment failure.

What Are Hydrostatic Relief Valves and How Do They Work?

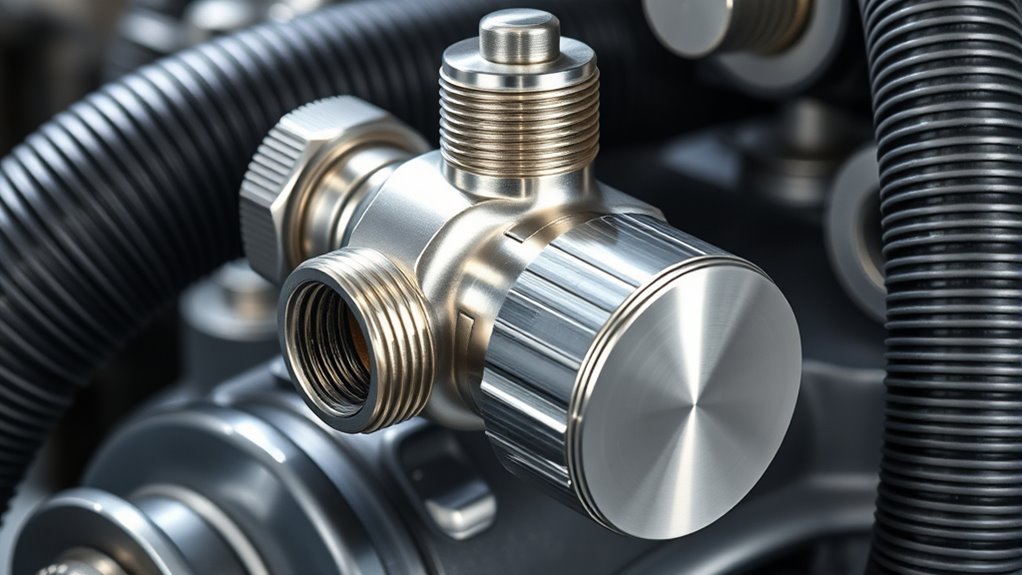

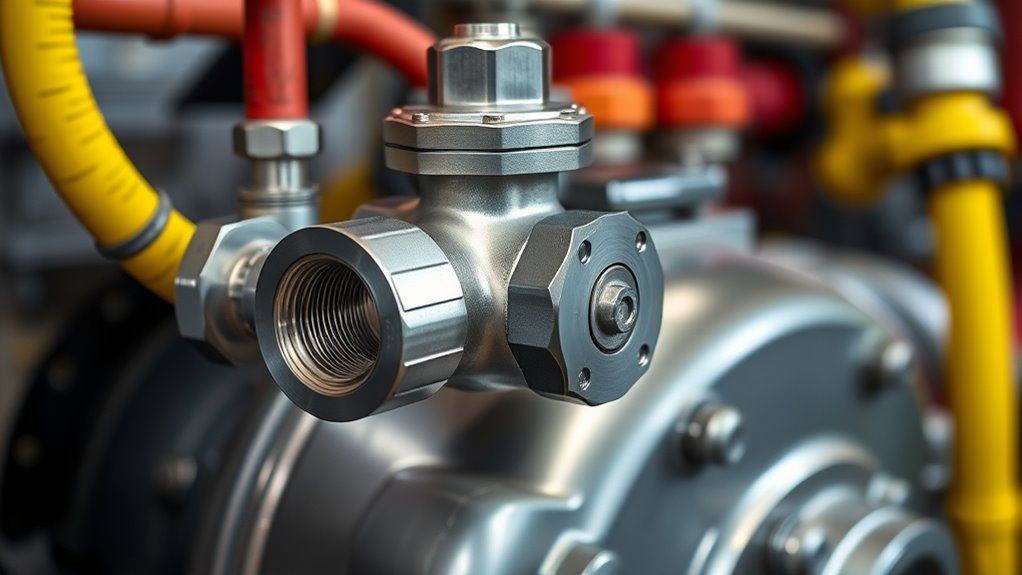

Hydrostatic relief valves are essential safety devices in hydraulic systems, designed to prevent excessive pressure buildup that could cause damage or failure. They work by continuously monitoring system pressure and opening when pressure exceeds a set limit. When this happens, the valve allows fluid to escape or divert, relieving pressure and protecting other components. Once the pressure drops back to a safe level, the valve closes automatically, restoring normal operation. These valves typically feature a spring-loaded mechanism calibrated to a specific pressure setting. You don’t need to manually operate them; they respond instantly to pressure changes. By maintaining safe pressure levels, hydrostatic relief valves help ensure your hydraulic system runs smoothly, reducing the risk of costly repairs or system breakdowns caused by overpressure. Additionally, selecting the appropriate pressure regulation components ensures optimal system performance and safety.

Why Choosing the Right Relief Valve Matters for Your Equipment

Choosing the right relief valve for your equipment guarantees maximum protection and efficient performance. The wrong valve can lead to system failures, costly repairs, or safety hazards. Here’s why selecting properly matters:

- Prevents Overpressure Damage: A suitable relief valve releases excess pressure, safeguarding your equipment’s integrity.

- Ensures System Reliability: Proper valves reduce downtime by functioning consistently under operating conditions.

- Extends Equipment Lifespan: Correct valve selection minimizes wear and tear, prolonging your machinery’s usability.

- Maintains Safety Standards: Proper relief valves prevent dangerous pressure buildup, protecting operators and surrounding assets.

- Supports AI-Enhanced Monitoring: Integrating AI-driven analytics can optimize relief valve performance and early fault detection.

In short, choosing the right relief valve isn’t just a small part of maintenance—it’s essential for safe, reliable, and cost-effective operation.

Signs Indicating It’s Time to Replace Your Relief Valve

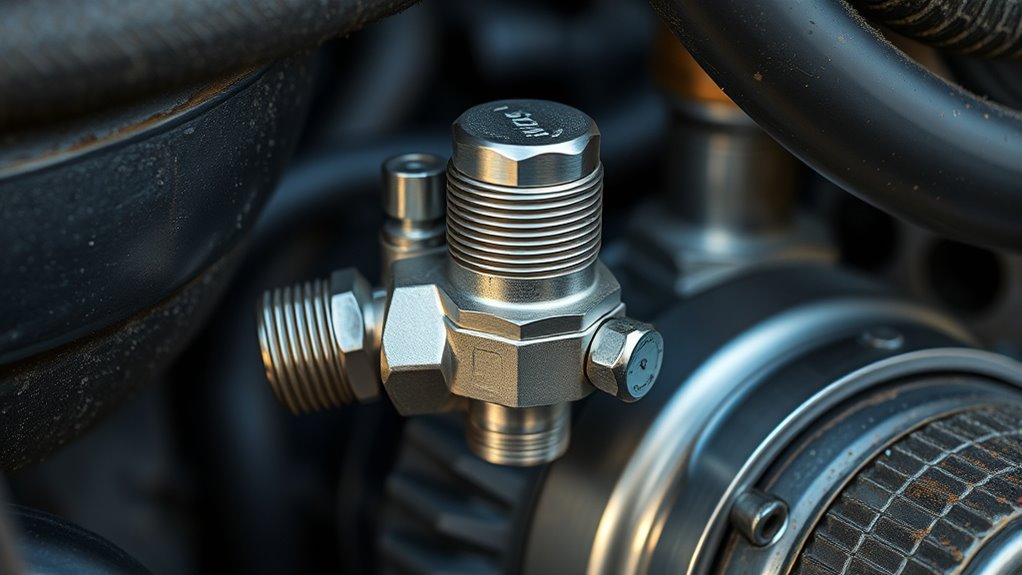

Regardless of how well your relief valve was initially selected or installed, it’s crucial to recognize when it’s time for a replacement. One clear sign is if the valve consistently leaks or weeps, indicating worn or damaged seals. Unusual noises like hissing or banging also suggest it’s not functioning properly. If you notice that the relief valve opens more frequently or at lower pressures than specified, it may be faulty or fatigued. Additionally, corrosion, rust, or dirt buildup on the valve can impair its performance and signal the need for replacement. Finally, if the valve fails to open during pressure tests or after maintenance, it’s a red flag. Ignoring these signs risks equipment damage and safety hazards, so timely replacement is essential.

Installation Tips for Ensuring Optimal Safety and Performance

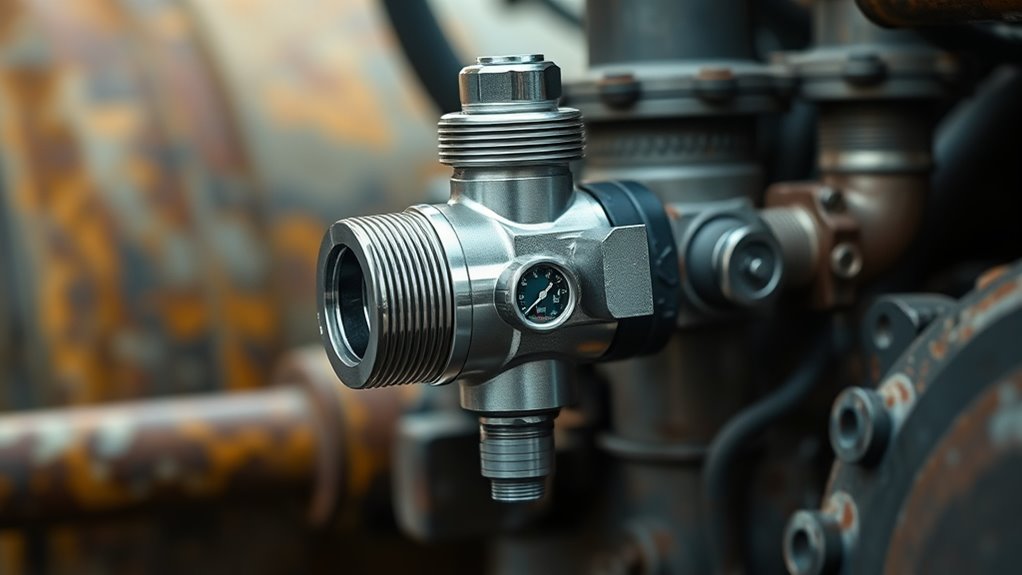

Proper installation is essential to guarantee your relief valve operates safely and efficiently. To do it right, follow these key tips:

Proper installation ensures safe, efficient, and long-lasting relief valve operation.

- Ensure the valve is installed in the correct orientation, following manufacturer instructions.

- Connect it to a clean, debris-free pipeline to prevent blockages or damage.

- Use compatible fittings and tighten connections securely without over-tightening.

- Verify the valve’s set pressure matches your system’s requirements before operation.

- Remember that proper installation practices contribute to the overall safety and longevity of the system.

Additionally, place the relief valve in a location that allows easy access for inspection and maintenance. Avoid placing it near heat sources or vibrating equipment, which can compromise its function. Proper installation not only enhances safety but also prolongs the valve’s lifespan, ensuring reliable performance over time.

Cost-Effective Maintenance Practices for Longevity and Reliability

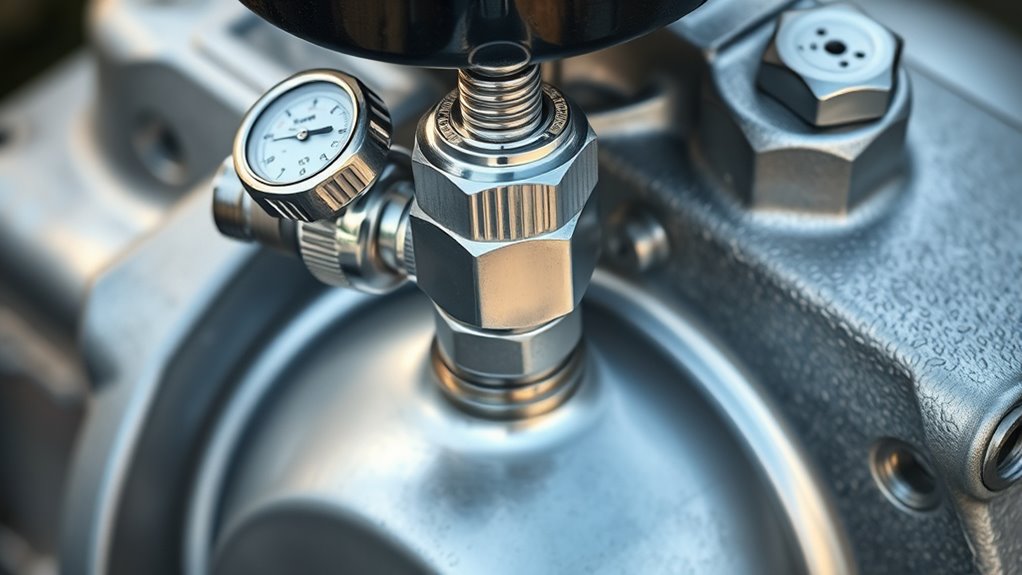

Regular maintenance is key to extending the lifespan and ensuring the reliable performance of your hydrostatic relief valves without breaking the bank. Start by inspecting your valves regularly for signs of wear, corrosion, or leaks, and address issues promptly. Keep the system clean and free of debris that could cause blockages or impair function. Use manufacturer-recommended lubricants and replace seals or parts as needed, rather than waiting for failure. Establish a routine maintenance schedule aligned with your system’s operational demands. Monitoring pressure levels and performing periodic system tests help catch problems early. Staying proactive prevents costly repairs and downtime. Additionally, understanding the importance of contrast ratio in projectors can help you select the right equipment for your setup, ensuring optimal image quality. Investing a little time and effort now guarantees your relief valves stay reliable, ultimately saving you money and safeguarding your equipment long-term.

Frequently Asked Questions

Can Hydrostatic Relief Valves Be Reused After Maintenance?

Yes, you can reuse hydrostatic relief valves after maintenance if you inspect them carefully. Check for any signs of damage, wear, or corrosion, and verify all components are clean and functioning properly. If the valve passes all inspections and tests, reassemble it correctly and verify its operation before reinstalling. Proper maintenance and inspection help extend the valve’s lifespan and ensure your system stays safe and reliable.

What Are the Environmental Impacts of Replacing Relief Valves?

Replacing relief valves can have positive environmental impacts if done responsibly. You reduce the risk of hydraulic fluid leaks, which can contaminate soil and water. Proper disposal of old valves prevents pollution, and using durable, high-quality parts minimizes frequent replacements. By maintaining and replacing valves correctly, you help conserve resources, reduce waste, and protect ecosystems, ensuring your equipment operates efficiently without harming the environment.

Are There Industry Standards Governing Relief Valve Safety?

Ever wonder if relief valves meet safety standards? You’ll find that industry standards like ASME and API set strict guidelines to guarantee safety and reliability. These standards dictate design, testing, and installation procedures, so you can trust that properly certified relief valves are built to protect you and your equipment. Always check for proper certification before installation—do you really want to leave safety to chance?

How Do Relief Valves Perform Under Extreme Temperature Conditions?

Relief valves are designed to perform reliably under extreme temperature conditions by using specialized materials and engineering. You’ll notice that high-quality valves maintain their function whether it’s scorching or freezing, thanks to temperature-resistant seals and metals. Regular maintenance ensures they respond promptly in emergencies. Keep an eye on manufacturer guidelines, and consider periodic testing to ensure your relief valves stay effective, no matter how harsh the environment gets.

What Innovations Are Emerging in Relief Valve Technology?

New relief valve innovations focus on smart materials that adapt to temperature changes, ensuring consistent performance. You’ll see sensors that monitor pressure and temperature in real-time, automatically adjusting valve responses for safety. Additionally, advanced coatings improve durability under extreme conditions. These advancements help you prevent failures, reduce maintenance costs, and enhance safety, making relief valves more reliable and efficient for demanding applications.

Conclusion

By paying attention to your relief valve’s subtle signals and performing regular care, you’re gently safeguarding your equipment’s longevity. These modest yet essential components act as silent sentinels, quietly preserving your system’s integrity without fanfare. When you prioritize their well-being, you’re not just maintaining machinery—you’re nurturing a foundation of reliability and peace of mind. Sometimes, it’s the quiet guardianship of a simple part that ensures your operation runs smoothly and confidently.